“Ship seals” can refer to different types of seals used in various applications on ships. These seals are crucial for maintaining the integrity and safety of marine vessels. Here are some common types of ship seals and their functions:

- Hatch Seals: These seals are used to ensure watertight and airtight closures for ship hatches and cargo holds. They prevent water ingress, maintain cargo integrity, and protect against harsh environmental conditions during sea voyages.

- Shaft Seals: Shaft seals, also known as stern tube seals or propeller shaft seals, are used in ship propulsion systems. They prevent seawater from entering the ship’s engine room through the propeller shaft opening while allowing the shaft to rotate smoothly.

- Bulkhead Seals: Bulkhead seals are installed in bulkhead penetrations to maintain the watertight integrity of compartments in case of damage to the ship’s hull. They are essential for ship safety and stability.

- Door Seals: Ships have various types of doors, including watertight doors and weathertight doors. Seals are used to ensure these doors provide proper sealing to protect the interior compartments from water and adverse weather conditions.

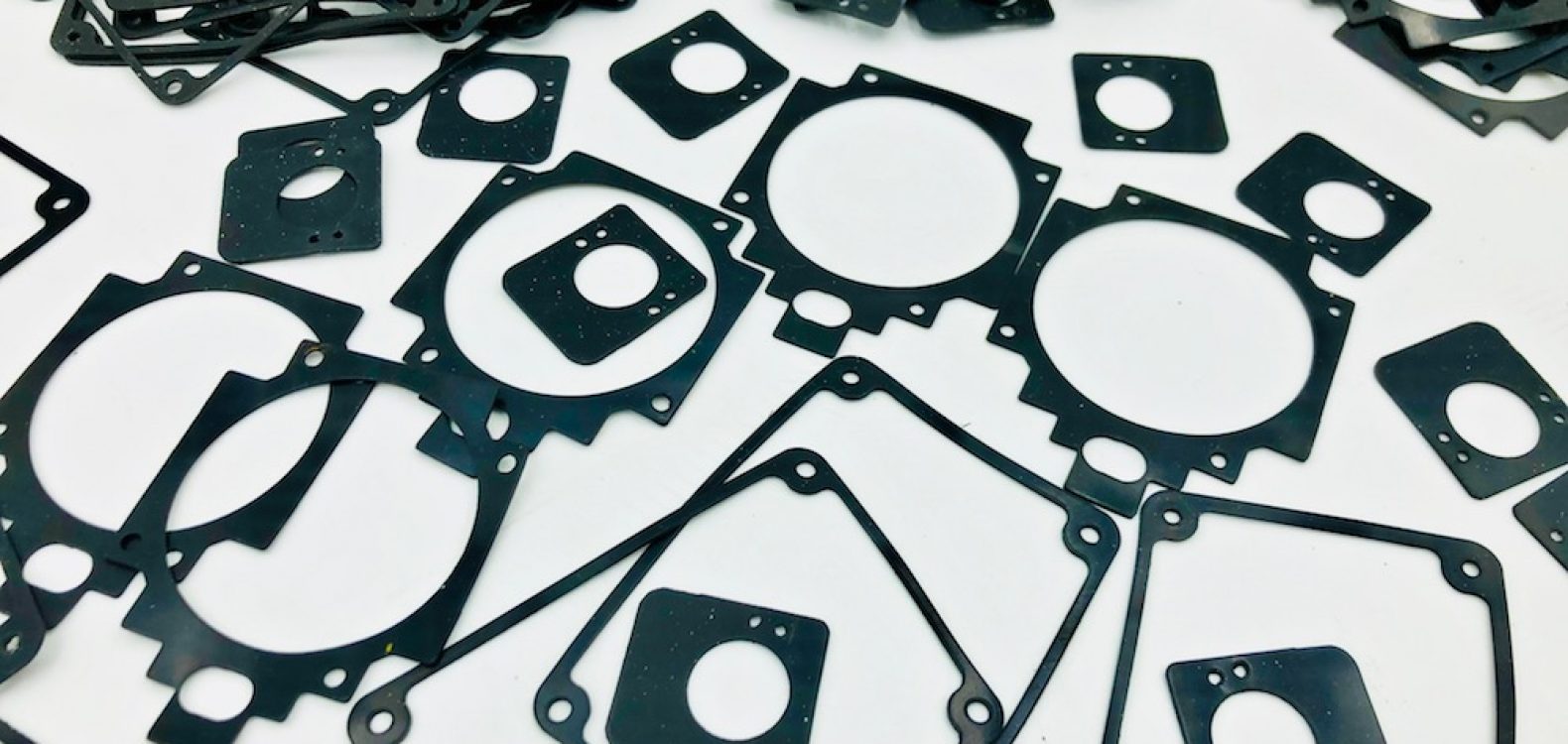

- Gasket Seals: Gaskets are used throughout ships in various applications, including engine rooms, pipe connections, and equipment access points. These seals prevent leaks and maintain the integrity of the ship’s systems.

- Cable and Pipe Penetration Seals: Ships have numerous cable and pipe penetrations through bulkheads and decks. Seals are used to prevent water ingress and maintain compartment integrity.

- Lifeboat Hatch Seals: Lifeboat hatch seals are used to ensure the watertight integrity of lifeboat compartments. They are critical for safety in case of emergencies.

- Porthole Seals: Porthole seals, also known as window seals, are used to prevent water ingress through ship windows while maintaining visibility for passengers and crew.

- Rubber Seals: Various rubber seals are used on ships for different applications, including watertight seals, gaskets, and vibration dampening. They help maintain the ship’s structural integrity and reduce noise and vibration.

The design and materials used for ship seals are carefully chosen to meet specific marine and safety standards. They must withstand the harsh marine environment, including exposure to saltwater, waves, and extreme temperatures. Regular maintenance and inspection of ship seals are essential to ensure they remain effective and compliant with safety regulations.

Overall, ship seals play a critical role in ensuring the safety, stability, and operational efficiency of marine vessels, from cargo ships to cruise liners and naval vessels.