GRP (Glass Reinforced Plastic) pipe seals, also known as fiberglass pipe seals, are specialized gaskets or sealing elements designed for use with GRP pipes. GRP pipes are made of composite materials, including layers of glass fiber reinforced with a polymer resin. These pipes are commonly used in various industrial applications, and GRP pipe seals are essential components to ensure proper sealing and prevent leaks in the pipe joints. Here’s more information about GRP pipe seals:

Features of GRP Pipe Seals:

- Chemical Resistance: GRP pipe seals are designed to withstand exposure to a wide range of chemicals, making them suitable for use in corrosive environments.

- High-Temperature Tolerance: These seals can handle elevated temperatures without losing their sealing properties, ensuring the integrity of the pipe system.

- Corrosion Resistance: Since GRP pipes are often used in applications where corrosion is a concern, GRP pipe seals are resistant to corrosion and degradation over time.

- Durability: GRP pipe seals are durable and have a long service life, reducing the need for frequent replacements.

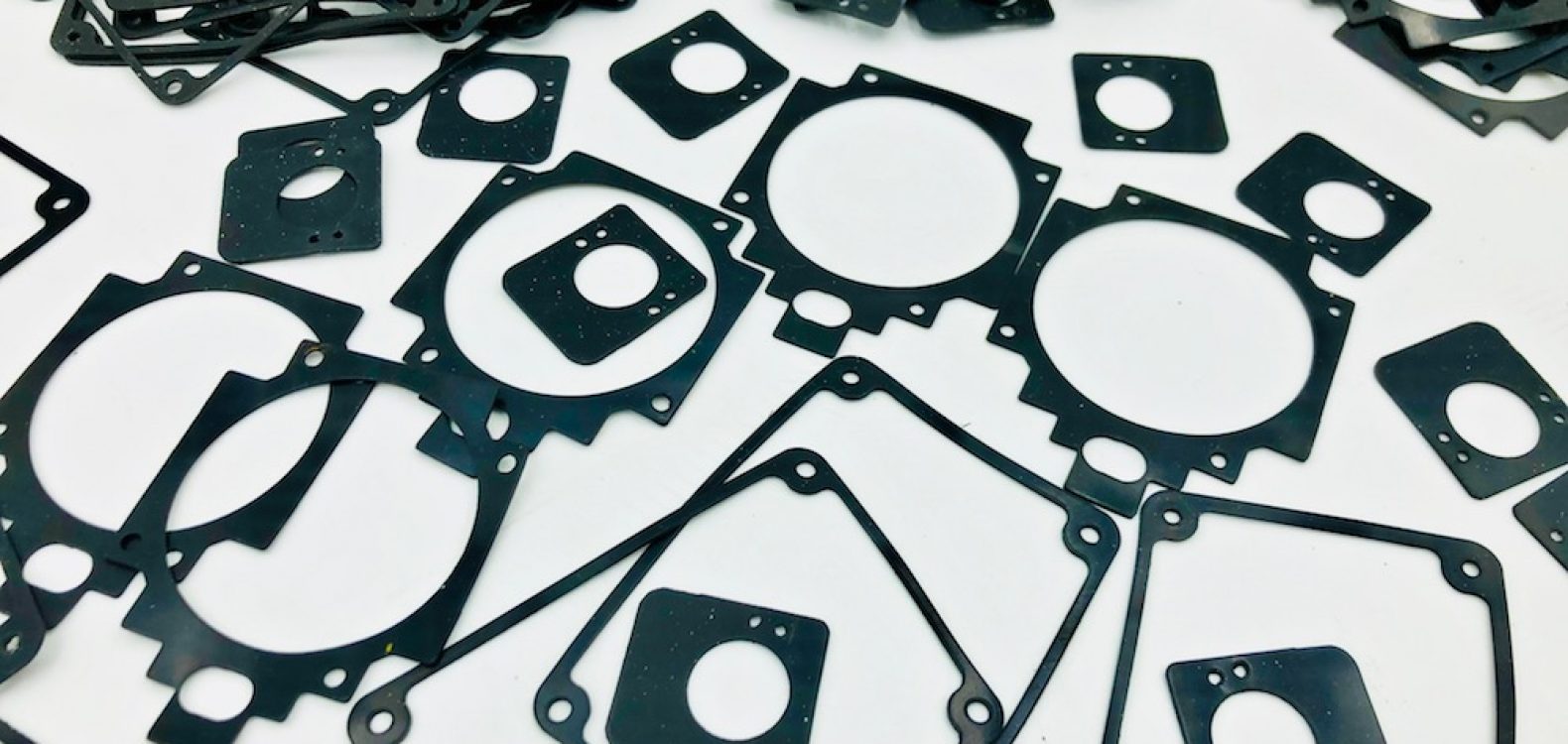

- Customization: These seals can be manufactured in various sizes and shapes to accommodate different pipe diameters and joint configurations.

Applications of GRP Pipe Seals:

GRP pipe seals are primarily used in applications where GRP pipes are employed, such as:

- Chemical Processing Plants: In facilities where a wide range of chemicals are transported through pipes, GRP pipe seals ensure leak-free connections and prevent chemical spills.

- Water and Wastewater Treatment: GRP pipes are commonly used for water distribution and wastewater collection. Sealing joints with GRP pipe seals helps maintain water quality and prevents contamination.

- Oil and Gas Industry: In oil refineries and petrochemical plants, where aggressive chemicals and high temperatures are common, GRP pipe seals ensure the integrity of the piping system.

- Power Generation: Power plants, including thermal and nuclear facilities, often use GRP pipes for various applications. Seals are essential to prevent leaks and maintain safety.

- Infrastructure Projects: GRP pipes are used in infrastructure projects like bridges, tunnels, and culverts. Sealing joints with GRP pipe seals helps ensure long-term structural integrity.

Manufacturing of GRP Pipe Seals:

The manufacturing process of GRP pipe seals involves precision engineering and the use of suitable composite materials. Here are the general steps:

- Material Selection: High-quality GRP materials that are compatible with the specific chemicals and environmental conditions of the application are chosen.

- Mold Design and Fabrication: Custom molds are designed and fabricated to create seals of the required shape and size.

- Lamination: Layers of glass fiber and resin are laid up in the mold, and the composite is cured under controlled conditions to form the seal.

- Trimming and Finishing: After curing, the seals are trimmed, and any necessary finishing touches are applied.

- Quality Control: Each seal is subjected to rigorous quality control testing, including dimensional checks, chemical resistance testing, and pressure tests.

GRP pipe seals play a crucial role in ensuring the integrity and safety of GRP piping systems in various industries. Their ability to withstand harsh environments and corrosive chemicals makes them an essential component for maintaining leak-free pipe connections.