Certainly, let’s delve into a comprehensive description of an auto door seals factory:

Factory Overview:

An auto door seals factory is a specialized manufacturing facility dedicated to producing a wide range of automatic door seals and related sealing products. These factories are essential in meeting the demand for high-quality seals used in various industries, including construction, automotive, aerospace, and more. Let’s explore the key aspects of such a factory:

1. Location and Infrastructure:

- Auto door seals factories are strategically located to ensure efficient transportation of raw materials and distribution of finished products.

- The factory’s infrastructure includes production floors, storage areas for raw materials and finished goods, quality control labs, administrative offices, and employee facilities.

2. Manufacturing Processes:

- Material Selection: The factory sources various sealing materials like rubber, silicone, neoprene, and thermoplastic elastomers, each chosen for its specific properties and applications.

- Molding and Extrusion: Sealing profiles and components are created through molding or extrusion processes. Molds are precision-engineered to produce consistent and accurate shapes.

- Cutting and Fabrication: Automated cutting machines and tools shape the seals to meet specific design requirements.

- Assembly: Some seals may require assembly of multiple components, such as attaching rigid bases, magnets, or adjustable mechanisms.

- Quality Control: At every stage, stringent quality control checks ensure that the seals meet industry standards for durability, performance, and safety.

3. Product Range:

- Auto door seals factories produce a wide variety of sealing products tailored to different applications:

- Threshold seals

- Weatherstripping seals

- Door bottom seals

- Automatic door bottoms

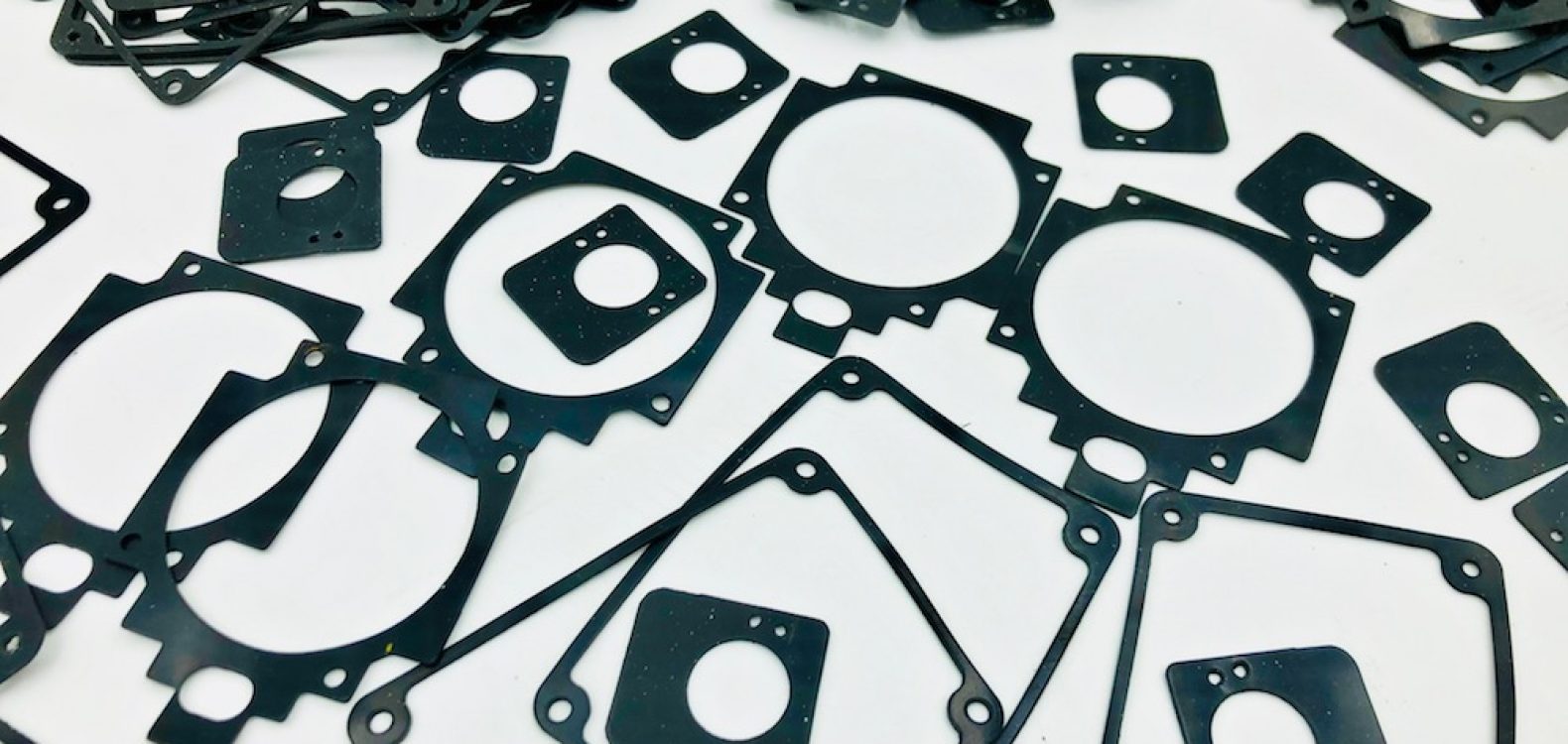

- Gasket seals

- Compression seals

- Sliding door seals

- Window seals

- These products come in different sizes, profiles, and materials to suit the diverse needs of customers.

4. Technology and Automation:

- Advanced machinery and automation are integral to the production process, ensuring precision and efficiency.

- Computer-controlled equipment facilitates consistent product quality and faster production rates.

- CAD/CAM software aids in design, prototyping, and mold creation.

5. Research and Development:

- Many auto door seals factories invest in research and development to innovate and improve seal designs and materials.

- R&D teams work on enhancing energy efficiency, durability, and customization options for seals.

6. Sustainability:

- Modern factories often prioritize sustainability by using eco-friendly materials, reducing waste, and adopting energy-efficient practices.

- Recycling and waste management programs help minimize the environmental impact.

7. Quality Assurance:

- Quality control measures include regular testing for properties like sealing effectiveness, compression resistance, UV resistance, and chemical compatibility.

- ISO and other industry certifications highlight the commitment to quality.

8. Customization and Client Engagement:

- Auto door seals factories often work closely with clients to develop custom sealing solutions for specific applications.

- Engineers and technical experts provide guidance and support to customers.

9. Distribution and Export:

- Finished products are distributed to various industries through a network of dealers, distributors, and direct sales channels.

- Export to international markets is common, requiring compliance with global standards and regulations.

10. Workforce:

– The factory employs a skilled workforce consisting of engineers, technicians, machine operators, quality control inspectors, and administrative staff.

11. Future Trends:

- Auto door seals factories keep an eye on industry trends, such as smart seals with IoT capabilities for automated building management systems and energy conservation.

In conclusion, an auto door seals factory is a vital manufacturing hub that combines technology, innovation, and precision to produce sealing solutions crucial for maintaining energy efficiency, security, and comfort in various industries and applications. These factories play a pivotal role in addressing the ever-evolving demands of the sealing industry while adhering to quality and sustainability standards.