Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are specialized sealing components used in concrete pipe systems. These seals are designed to ensure a tight and reliable connection between concrete pipes, preventing the leakage of fluids (such as wastewater, stormwater, or sewage) and the intrusion of soil or contaminants into the pipe system. Here is more information about concrete pipe seals:

Types of Concrete Pipe Seals:

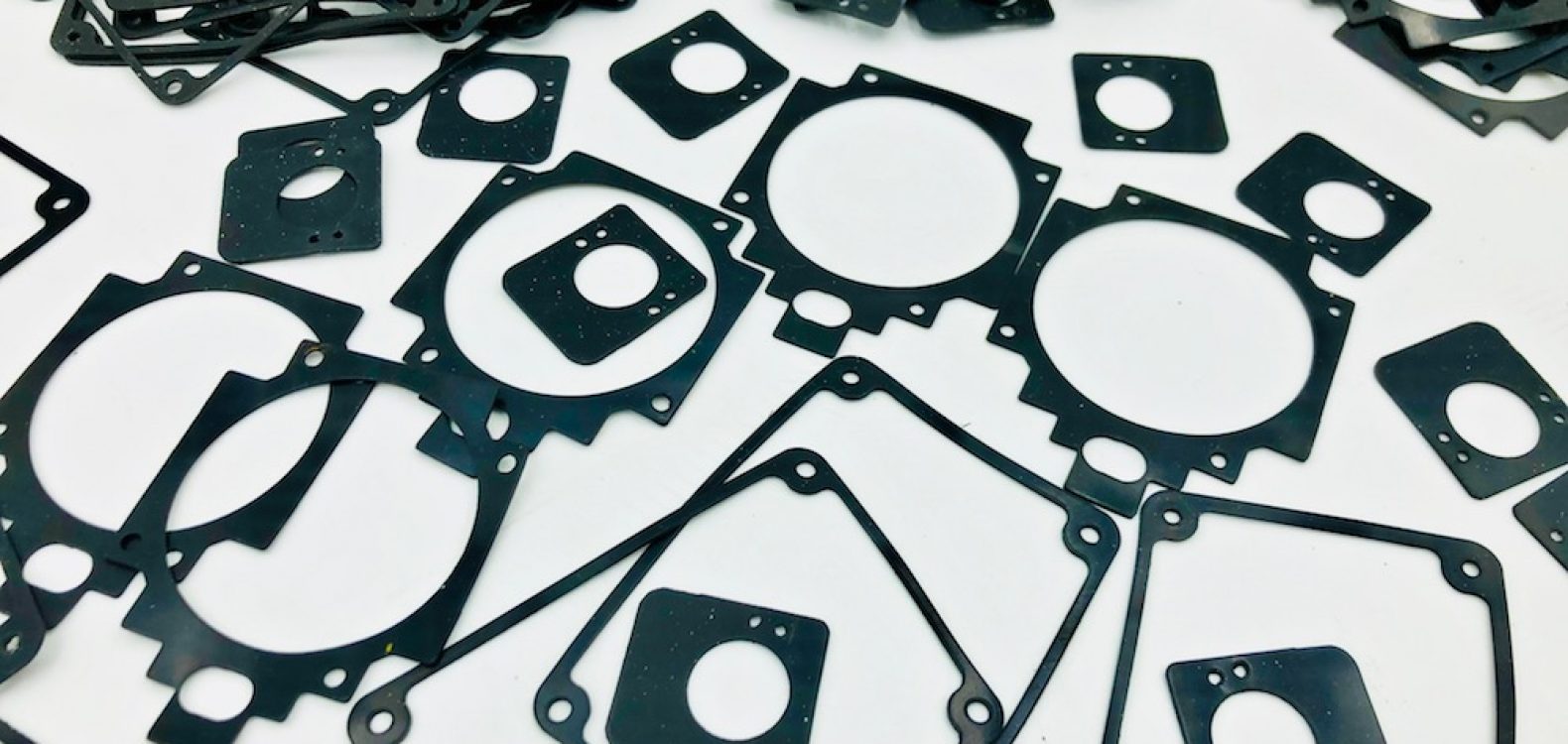

- Flexible Rubber Gaskets: These are the most common type of concrete pipe seals. They are typically made of elastomeric rubber materials such as EPDM (ethylene propylene diene monomer) or Nitrile rubber. These gaskets create a secure and flexible seal between the concrete pipe joints.

- Compression Seals: Compression seals are designed to provide a watertight seal by compressing the rubber gasket within the pipe joint. They are often used in larger concrete pipe systems and help accommodate joint movement.

- Mastic or Lubricated Seals: Mastic or lubricated seals may consist of a lubricated rope, compound, or mastic material. They are placed in the joint to create a sealing effect and prevent infiltration of soil and groundwater.

- Reinforced Concrete Pipe Joints: In some cases, the joint itself is designed to provide a sealing function. For example, tongue-and-groove joints are used in reinforced concrete pipes to create a mechanical seal.

Features and Benefits:

- Watertightness: Concrete pipe seals are essential for maintaining the watertightness of the pipe system. They prevent leakage of fluids from the pipes, ensuring the efficient transport of wastewater, stormwater, or sewage.

- Soil and Contaminant Resistance: These seals protect against the intrusion of soil, sediment, and contaminants into the pipe system, which can cause blockages and reduce the pipe’s lifespan.

- Durability: Concrete pipe seals are made from materials that are resistant to environmental factors, including moisture, chemicals, and UV exposure, ensuring long-term performance.

- Easy Installation: They are relatively easy to install during the pipe joining process, making them a practical choice for construction and maintenance.

Applications:

Concrete pipe seals are commonly used in various infrastructure and construction applications, including:

- Sanitary Sewer Systems: They are used in the construction and maintenance of sanitary sewer systems to ensure the proper conveyance of wastewater.

- Stormwater Drainage: In stormwater management systems, concrete pipe seals help prevent infiltration of groundwater and contaminants into stormwater pipes.

- Culverts and Drainage Structures: Culverts and other drainage structures benefit from concrete pipe seals to maintain their functionality.

- Water Treatment Plants: In water treatment facilities, concrete pipe seals help control the flow of water and wastewater.

- Industrial Applications: Concrete pipe seals may be used in industrial settings where large concrete pipes are employed for various purposes.

Proper selection and installation of concrete pipe seals are critical to the performance and longevity of concrete pipe systems. These seals are engineered to meet specific industry standards and should comply with local regulations to ensure the integrity of the pipe network.