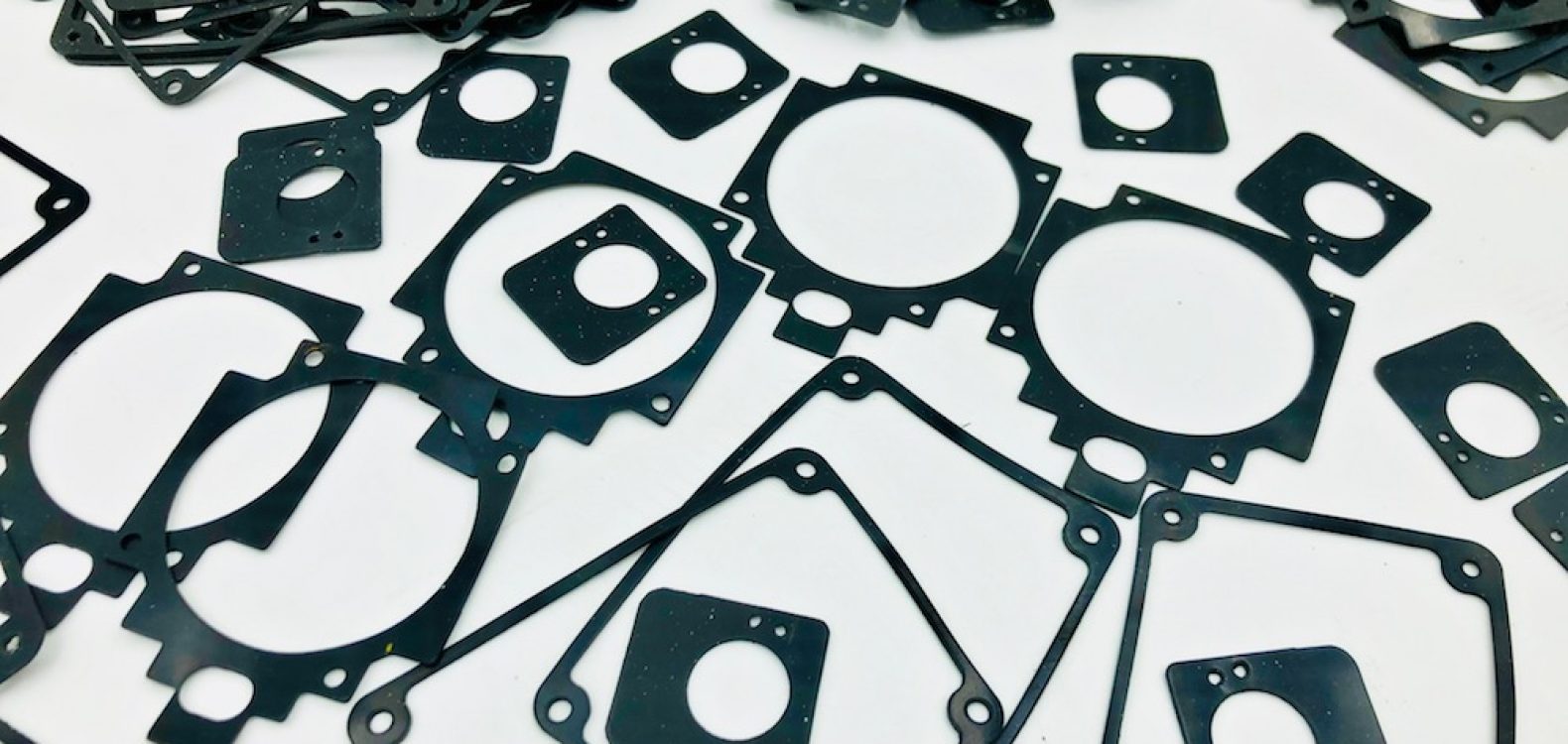

EPDM (Ethylene Propylene Diene Monomer) rubber seals, also known as EPDM gaskets or EPDM rubber gaskets, are commonly used sealing components known for their excellent resistance to weathering, UV radiation, ozone, moisture, and a wide range of chemicals. These seals are widely utilized in various industries for sealing applications to prevent leakage, maintain airtightness or watertightness, and provide insulation. Here’s more information about EPDM rubber seals:

Features and Benefits:

- Weather Resistance: EPDM rubber seals are highly resistant to outdoor environmental factors, including sunlight, rain, and temperature fluctuations. They maintain their sealing properties over extended periods of exposure to harsh weather conditions.

- Chemical Resistance: EPDM rubber is compatible with many chemicals, including acids, bases, and oils, making it suitable for applications where exposure to various chemicals is a concern.

- Temperature Tolerance: EPDM rubber can perform reliably in a broad temperature range, from approximately -40°C (-40°F) to 150°C (302°F), depending on the specific formulation and application requirements.

- UV and Ozone Resistance: EPDM rubber is resistant to the deteriorating effects of UV radiation and ozone exposure, making it ideal for outdoor and sunlight-exposed applications.

- Flexibility and Elasticity: EPDM rubber is highly flexible and elastic, allowing it to conform to irregular surfaces and maintain a secure seal even under varying conditions.

- Low Gas Permeability: EPDM rubber has low gas permeability, making it suitable for applications where airtight or watertight seals are essential.

- Electrical Insulation: EPDM rubber is an excellent electrical insulator, making it suitable for sealing and insulating electrical enclosures, connectors, and components.

- Durability: EPDM rubber seals are known for their durability and long service life, reducing the need for frequent replacements.

Applications of EPDM Rubber Seals:

EPDM rubber seals are utilized in a wide range of industries and applications, including:

- Automotive: EPDM rubber seals are used in automotive applications for weatherstripping, door seals, window seals, gaskets, and various other sealing components.

- Construction: In the construction industry, EPDM seals are used for sealing doors, windows, roofing systems, HVAC equipment, and expansion joints.

- Electrical and Electronics: EPDM seals are employed in electrical enclosures, cable glands, and electrical connectors to provide sealing, insulation, and environmental protection.

- Marine: EPDM rubber is used in marine applications for sealing boat hatches, portholes, doors, and other marine components that require watertight and weathertight seals.

- Industrial: EPDM seals are used in industrial applications for sealing pipe connections, flanges, tanks, equipment enclosures, and chemical processing equipment.

- Aerospace: In aerospace applications, EPDM seals may be used in aircraft components, such as door seals, window seals, and gaskets, where reliable sealing is essential.

- Food and Beverage: EPDM rubber seals are employed in the food and beverage industry to seal processing equipment and maintain sanitary and hygienic conditions.

Manufacturing and Customization:

EPDM rubber seals can be manufactured using various processes, including extrusion, molding, or cutting, depending on the specific requirements of the application. They can be custom-designed to fit various shapes, sizes, and sealing profiles to meet the needs of specific applications.

In summary, EPDM rubber seals are versatile sealing components known for their resilience and resistance to environmental factors, chemicals, and extreme temperatures. Their durability and adaptability make them a popular choice for sealing and gasketing applications in a wide range of industries.